Novel Saccharomyces cerevisiae-loaded PVP/SiO2 nanofiber for wound dressing prepared using electrospinning method

Nahyun Kim1, Ga-Young Sim1, Chul hyun Park1, Minseok Kang1, Youn seop Kim1, Dongho Lee1, Kyungho Baek Ph.D1,2, Han-gon Choi Ph.D2, Sung Giu Jin Ph.D1.

1Pharmaceutical Engineering, Dankook University, Cheonan-si, Korea; 2Pharmacy & Institute of Pharmaceutical Science and Technology, Hanyang University, Ansan-si, Korea

Introduction: This study developed composite nanofiber wound dressings composed of polyvinylpyrrolidone (PVP) and silicon dioxide (SD), loaded with Saccharomyces cerevisiae (SC), for efficient drug delivery in wound healing applications. PVP is a biocompatible polymer with excellent solubility and processability, though it requires reinforcement to improve mechanical properties. The incorporation of SD enhances the structural integrity of PVP-based nanofibers. Nanofibers offer a high surface area to volume ratio and porous structure, making them ideal for controlled drug release. Using the electrospinning technique, SC-loaded PVP/SD nanofibers were fabricated, enabling the incorporation of heat-sensitive components in a cost-effective manner.

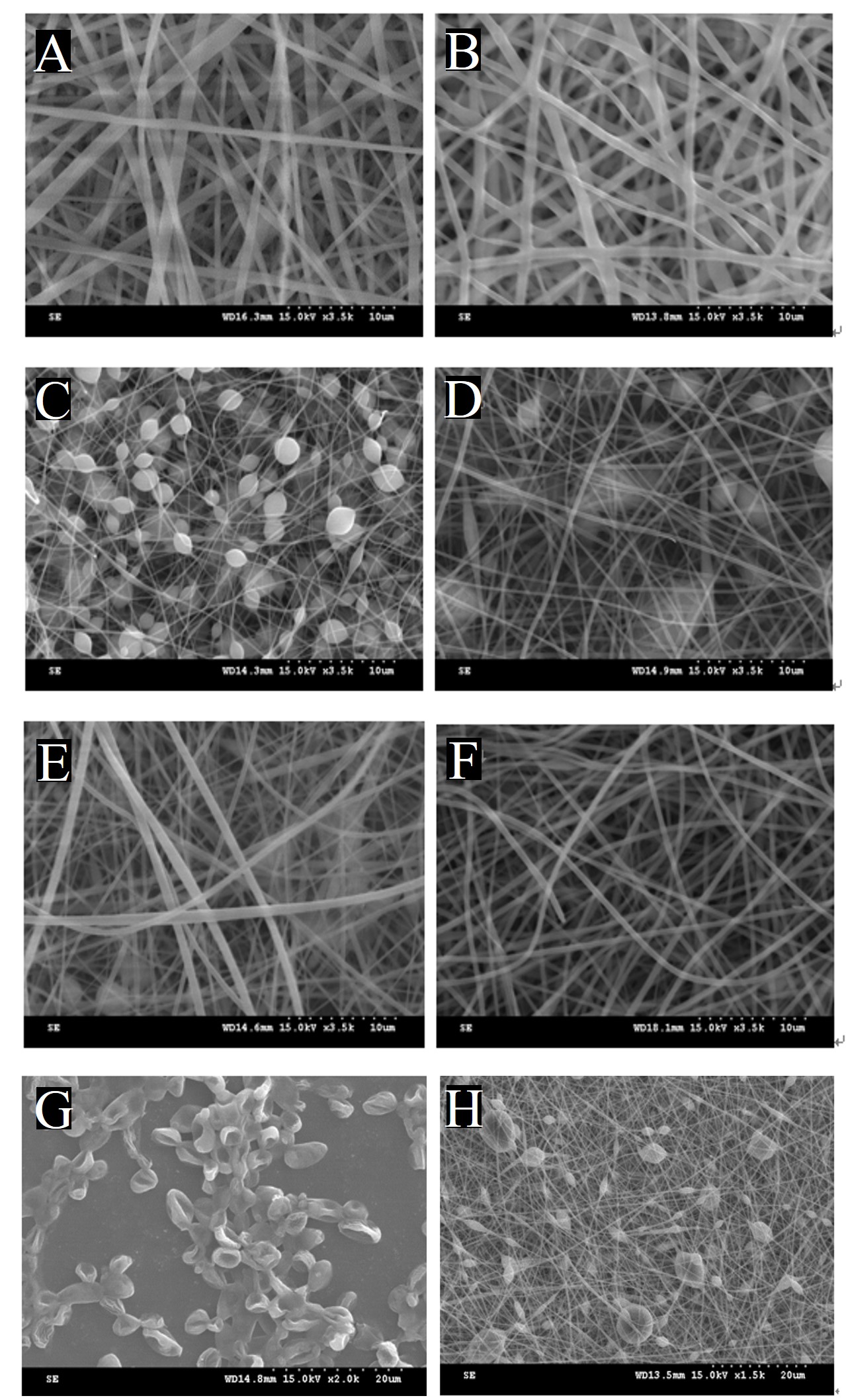

Methods: SC-loaded PVP/SD composite nanofibers were prepared via electrospinning. PVP was dissolved in ethanol or ethanol-water mixtures, and SD particles were dispersed within the solution. SC was added, and the mixture was electrospun under controlled conditions. The resulting nanofibers were collected on aluminum foil and vacuum dried. Their morphology was analyzed via SEM, DSC, XRD, and FTIR were used to study physicochemical properties. Mechanical strength and elongation at break were tested, and SC release was measured using the USP Apparatus V method.

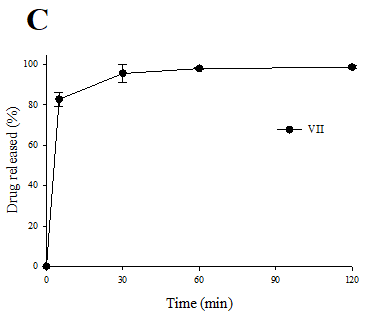

Results: The nanofibers were successfully produced, with solvent composition playing a crucial role in morphology. A higher ethanol content in the solvent yielded uniform, bead free fibers with the smallest average diameter of approximately 625 nm. SEM analysis confirmed the even distribution and encapsulation of SC within the fibers. DSC, XRD, and FTIR data revealed that SC remained in an amorphous state and showed no strong molecular interaction with PVP or SD. Mechanical testing showed that SC-loaded fibers had slightly improved tensile strength but reduced elongation, and overall had lower mechanical performance compared to conventional dressings. Drug release studies demonstrated that SC was fully released within 30 minutes, highlighting the fibers' rapid delivery capability.

Conclusion: The SC-loaded PVP/SD composite nanofibers developed in this study were successfully fabricated via electrospinning, producing uniform, bead-free fibers with stable SC encapsulation. Optimizing the solvent composition, especially by increasing ethanol content, improved fiber morphology. SC was released rapidly within 30 minutes, making the system suitable for fast-acting wound dressings. Furthermore, the nanofibers showed no adverse molecular interactions. Beyond wound healing, these nanofibers also hold potential as scaffolds in tissue engineering, particularly for regenerating skin, oral mucosa, and epithelial tissues using bioactive agents like SC.

This work was supported by a National Research Foundation of Korea (NRF) grant under the Korean government (MEST) (No. RS-2023-00208448). .

[1] Electrospinning

[2] Composite nanofibers

[3] Wound dressing

[4] Saccharomyces cerevisiae